How can industrial parks embrace automation?

- Identify the areas that need automation

- Educate the workforce

- Integrate cybersecurity solutions

- Think about the budget carefully

- Track the results

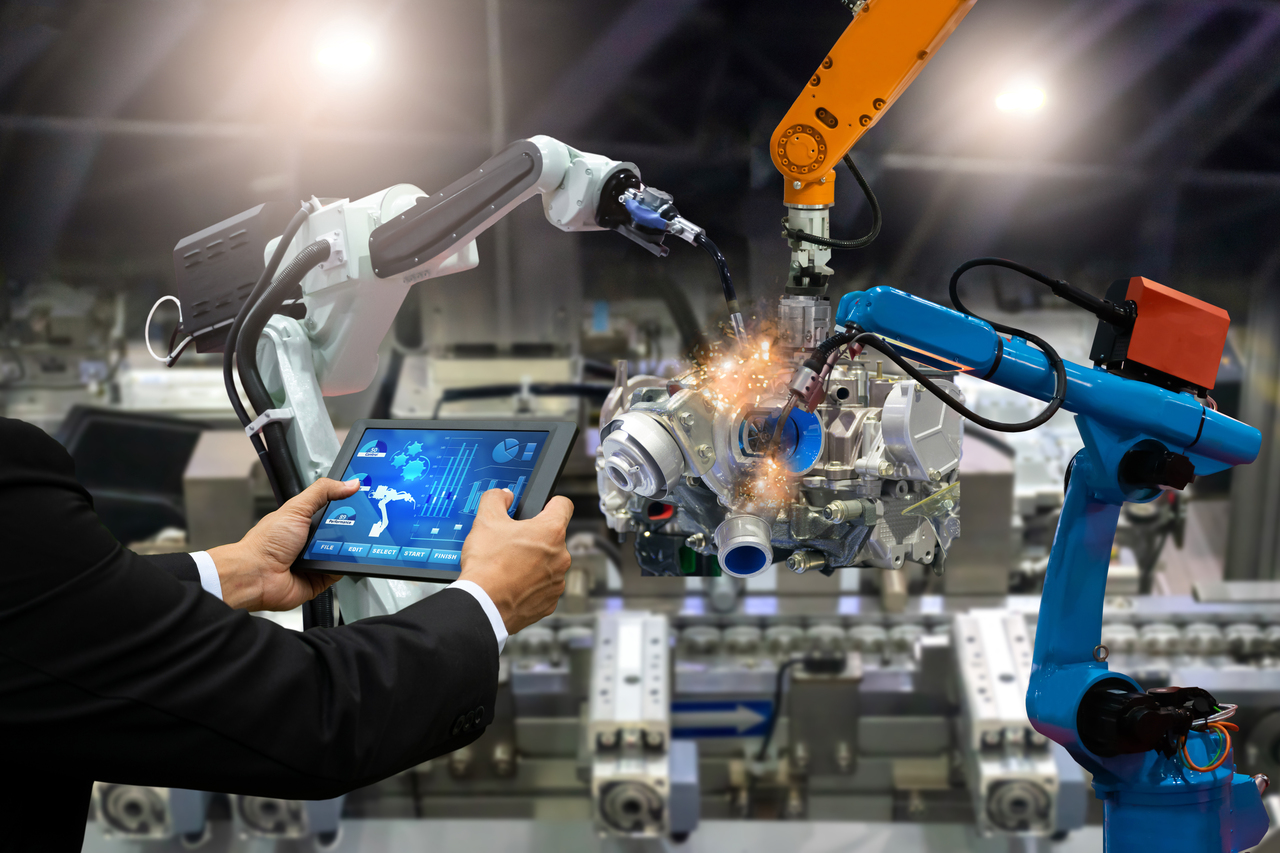

There’s no doubt that there have been tremendous developments in technology during this era. Among those developments, automation is a procedure that offers plenty of advantages for industrial parks. With that being said, we are here to talk about how industrial parks can embrace automation.

Industrial parks are known for their state-of-the-art infrastructure, competent management teams, and comprehensive customer service. To further enhance productivity and efficiency, adopting automation should be prioritized.

We here at SPPI continue to serve industrial machinery companies in the Philippines that only benefited from embracing automation. That’s why for this article, we’ve rounded up some ways to ramp up operations and ensure that firms integrate automation at their core. Read on!

Identify the Areas That Need Automation

Research on the pieces of automation equipment and how they function. Ensure that each one will help your organization reach peak performance.

Remember that this requires a large amount of capital. Acting harshly and immediately implementing automation without proper thought and research can do more harm than good.

Machines cannot keep up with human creativity. Do not use automated machinery for design jobs. Doing so can turn your investment into useless additional expenses.

It’s vital to clearly identify the areas that are ready for automation. Carefully think about the processes that are hindering operations. For example, in the assembly line, are there areas wherein errors often recur? If yes, there is machinery that can eliminate such bottlenecks.

Educate The Workforce

Contrary to popular belief, automation does not have to completely destroy the workforce. It is possible for new machinery and humans to work together. However, there will be a certain shift.

New technology is changing the nature of operations. According to experts, automation in the workplace could improve productivity and even create more jobs if planned well.

Rather than instilling fear and terminating your workers, train them to grow their skills instead. Make them pay attention and analyze how automation works to improve operations.

It is also important to convey that automation eliminates repetitive tasks. By nature, humans want to be able to solve problems – not do repetitious movements such as opening boxes and other basic assembly line processes.

Remember that automation can also help workers be promoted to higher-level positions that machinery cannot fulfill. They can take on a role that requires creativity and decision making for success, while machinery can bear the heavy and physical workload loads instead.

Integrate Cybersecurity Solutions

Automation is unlikely to be freed from potential security breaches. Since it is an innovation that is connected to several networks in order to function, it is prone to threats as well.

Cyber breaches have been causing organizational problems for years now. Currently, no industry is safe from this, not even industrial parks. Unfortunately, hackers are coming up with more methods to steal information and develop malware.

If you embrace automation, it will serve as a long-term asset to the firm. It’s vital that you integrate state-of-the-art cybersecurity solutions.

Think About The Budget Carefully

Incorporating automation into operations is far from cheap. The new machines being sold on the market can range anywhere from hundreds of thousands, millions, to even billions. Let’s not forget that several parts may be needed to support the machines as well.

Think about whether your organization can carry the budgetary requirements beforehand.

This brings us back to the part about identifying the areas that need automation. Since automation can be costly, it would not be practical to bring in a full set of machinery to overhaul the old equipment.

Also, consider starting small when implementing automation. It would enable you to know if the machinery will enhance operations. Once the organization understands the setup better, you can start implementing more procedures.

Track The Results

When you finally decide to integrate automation into your business processes, it would be wise to track the results. This would help in recognizing the direct advantages and benefits.

Automation is not a one-time activity. There will be changes in the system and management should have a good business plan for this. It is critical for stakeholders to be informed during the roll phase as well. Doing so would avoid problems when errors occur.

Tracking would also offer insight as to which other areas can utilize automation. Think long-term. Choose whether to replace, upgrade, or get rid of the new machinery to put a stop to costly risks in the future.

Key Takeaway

If you’re wondering about how industrial parks can embrace automation, we’ve stated the five ways to do so. These methods would help you incorporate automation into your daily operations smoothly.

Automation can work wonders for industrial parks and drive immense growth. If done correctly, it can optimize supply chains, improve worker productivity, and increase market competitiveness.

Ensure that you successfully deploy the procedure to lower risks and improve operational efficiency.