What are the things you need to know about industry 4.0?

- The Building Blocks of Industry 4.0

- The Opportunities For Industrial Companies

- The Risk And Challenge Of Adapting

There’s no doubt that we are living in the age of technology today. Everywhere you look electronics are present. People rely on their smartphones regularly and technological parks are popping left and right. The era of industry 4.0 in the Philippines is upon us. But what do we really need to know about the country’s incoming fourth industrial revolution?

Simply put, industry 4.0 is all about the digital transformation of industrial markets. Smart technology is at its forefront. Think of it as autonomous systems that can connect with each other without needing human involvement.

From the energy industry, transportation, construction, chemicals, oil, mining, to even the manufacturing industry, industry 4.0 will encompass it all. With all-in access to data, smart machines and processes are going to completely revolutionize the way we work, live, and interact.

According to the United Nations, this will shape societies in the future. Today we will be taking a look at the major points of industry 4.0 and why it plays such a big part in a country’s economy.

The Building Blocks of Industry 4.0

Industry 4.0 has major building blocks, including the Internet of Things (IoT), artificial intelligence (AI), cloud computing, additive manufacturing (AM), and big data analytics.

Internet of Things (IoT)

To start it off we’ll talk about IoT. With this tool, all smart devices have an established connection with each other. All information can be transmitted and processed remotely. Every object can be monitored and controlled using digital networks.

In the Philippines, IoT is already being adopted, although to varying degrees. Some examples are smart transportation systems, voice-controlled homes, smart power grids, and smart weather devices.

Artificial Intelligence (AI)

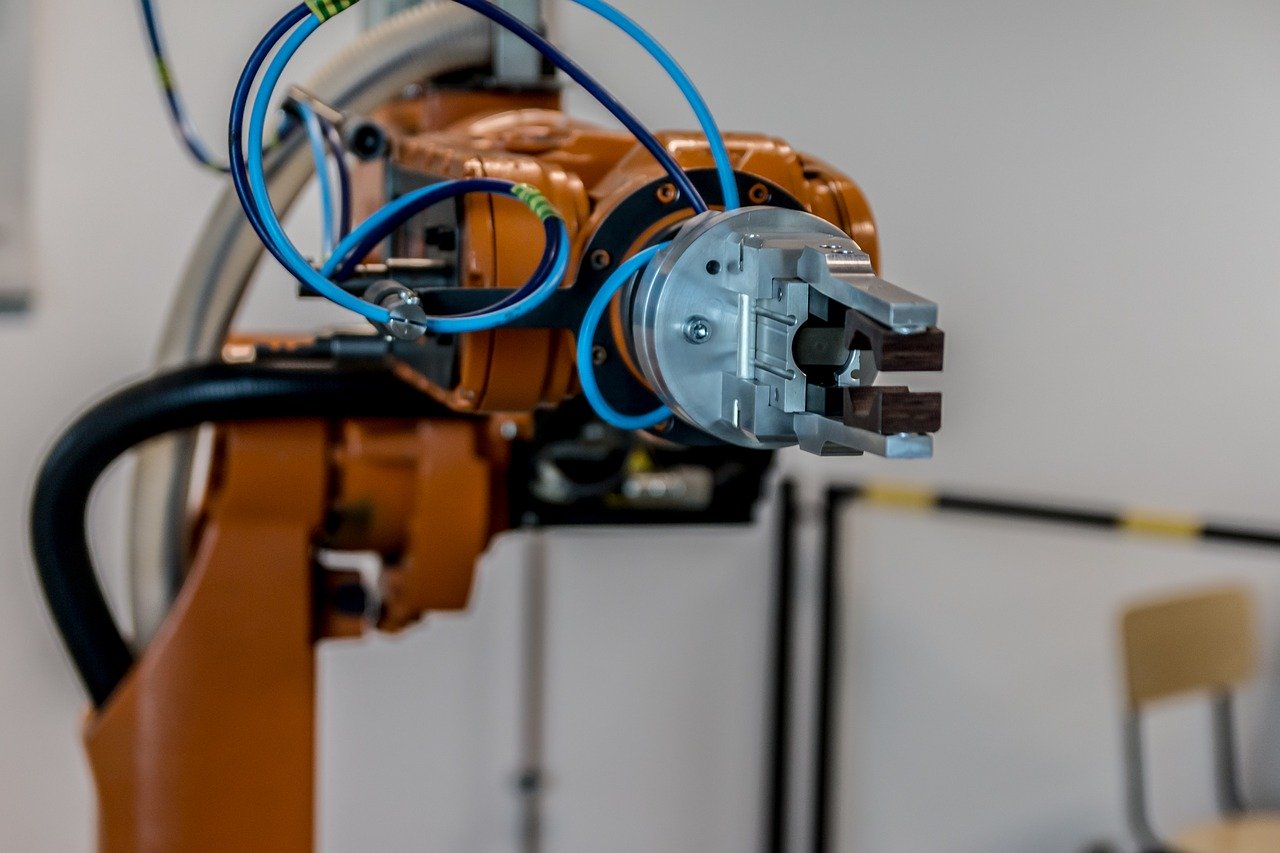

Up next is AI which is also known as machine intelligence. Here, intelligence is programmed in machines. This is where computer systems gain human or animal reasoning and thinking skills. Today, we use AI for telecommunications and packaging consumer goods.

Cloud Computing

Cloud computing deals with data storage and sharing through computer powered systems – without the need for user management. The Philippine government is already making use of cloud computing through GovCloud. LGUs are reaping the benefits of being connected to the same cloud by easily duplicating documents.

Additive Manufacturing (AM)

AM is also called 3D-printing. Through this tool, three-dimensional models can easily be created from a computer-aided design (CAD) file. Every material that needs to be incorporated in the product can be assembled layer by layer. Traditional machinery molds materials manually, but with 3D-printing, companies can efficiently improve their manufacturing processes.

Big Data Analytics

Big data analytics deals with making use of descriptive and predictive analytics. With this, companies can easily predict market trends, gather client information, and interpret customer behaviors through transactions.

The Opportunities For Industrial Companies

Industrial companies need to keep a close eye on industry 4.0 because its impacts are far-reaching. Entire value chains will be changed – manufacturers, suppliers, and workers will be affected.

For one, companies can use these technological tools for expanding their business and tapping into new markets. Data analytics can easily make this possible.

Industry 4.0 entails more efficient production processes with the help of AI. Efficiency means lowering the risk of costly mistakes. This could mean bigger savings. Moreover, industries can deliver the right products to consumers which in turn can garner increased revenues. Higher efficiency equates to better customer service.

The Risk And Challenge Of Adapting

While it’s true that the opportunities for adapting industry 4.0 are endless, a great number of risks and challenges also come with it. If industrial companies want to benefit from the fourth industrial revolution, they must be prepared.

First off, workers will have to adapt habits to cope with the rise of an all-new technological industry. They will need to gain the necessary skills to work hand-in-hand with automated machines. Let’s not forget the risk of job loss.

Cybersecurity issues may also arise as all devices are connected to the IoT. This makes organizations vulnerable to cybersecurity breaches. The amount of sensitive information that companies keep can be easily accessed by computer networks.

In the Philippines, one can argue that network reliability will be a major challenge. The advantages of industry 4.0 can only be attained if network connections are fast and reliable.

Lastly, reaping the benefits of industry 4.0 will require substantial capital investment. It can be costly for every company to make the switch.

Key Takeaway

When it comes to adapting Industry 4.0 in the Philippines, one cannot deny the benefits it will provide our economy. In an attempt to keep up with the demand for globalization, industrial companies must align their strategies carefully. Companies will need to develop sustainable models and continuous learning is crucial.

Industry 4.0 is the future and industries need to level up with the “new normal’ of doing business.